In order to deal with the damage after storms as a farmer, clearance of land with vegetation for construction purposes as a landowner, and the management of your home garden, you need a wood chipper with the capability to run smoothly even while operating heavy load and produce good quality output.

Screw wood chippers can perform the chipping for commercial as well as domestic purposes. These chippers can be electric or tow-mounted engine vehicles. Diesel-powered screw wood chippers are also on the market.

A thorough reading of this article will help you to be well-conversed with a screw wood chipper. Listed below discussion is the answer to all possible questions you may get while operating, maintaining, and buying a screw wood chipper.

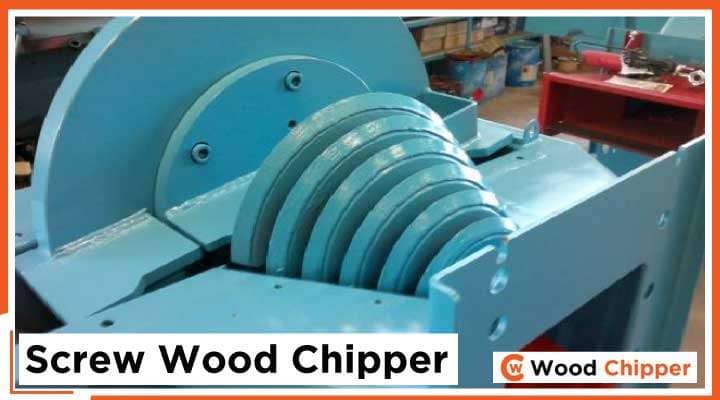

What Is A Screw Wood Chipper?

Screw wood chipper is a unique and varied design type of wood chipper. In the screw chipper, a conical shape blade is installed that cuts the material into fine chips.

The rotation of these blades is set parallel to the direction of wood material feed in the hopper as the material takes in by the coiling movement of blades.

It is used to pulverize different wood materials, such as slabs, tree trimmings, logging waste, etc. It can handle both frozen and dry blocks of wood quickly.

Screw wood chippers have both commercial and domestic applications depending upon the engine. The bigger the machine, the more powerful it is, and the heavier load it can transform.

The Working Mechanism Of A Screw Wood Chipper

A screw wood chipper performs its mechanism of action in a series of steps. The operation is simple and reliable.

A sample is placed in an automatic feed hopper that moves the wood material into the cutting machine.

The screw blade captures the feedstock and pushes it into the chipper. The spiral-shaped blades on rotation cut the wood into chips at the same time.

The speed of the blade rotation increases, but the chipping rate remains the same to ensure the production of uniform chips.

The revolving blades are connected to the flywheel, where the rotating wings expel the chips out of the chipper.

Benefits Of Having A Screw Wood Chipper

Screw wood chippers offer multiple advantages compared to other systems. The main benefits of a screw wood chipper are listed below.

1. Homogenous Chips

Screw wood chippers can produce good quality uniform chips. In addition, the made chips are splinter-free and deprived of excess amount of sawdust and foreign waste.

2. Quiet Performance

Screw wood chippers work on the principle of pulley cut rather than the hammering cut mechanism to perform chipping. As a result, these chippers are not attributed to continuous load, ultimately a quieter operation.

3. Easy And Economical Maintenance

Due to a relatively less complicated design, screw wood chippers have low maintenance costs. As a result, the parts of the machine do not tend to corrosion and weariness. As a result, the replacement of chipper parts is not as frequent as other types of chippers.

4. Self-Retracting Principle

Screw wood chippers do not require feeding devices to capture the feedstock. Instead, the screw-shaped blades draw in wood material into the chipper, ultimately contributing to cost reduction and low machine weight.

Limitations Of A Screw Wood Chipper

Every type of chipper has its drawbacks that may constrain its marketing, and so has the screw wood chippers.

In the case of a screw wood chipper, the mechanism of action attributes to the limitation of its use. The following negative points create hassle while performing chipping with a screw wood chipper.

- The self-retracting ability of screw wood chippers is an advantage, but in this way, adjusting the speed of the feeding is not possible. It is damaging if the machine is fed with a heavy load of feedstock, there is no way out to slow down the speed to reduce the feeding material, so there might be a chance of clogging in the chipper.

- The design and mass of a screw wood chipper are less than that of its counterparts, drum chipper, and disc chippers. These chippers cannot deal with the increased inertial force, which means that they have little energy and cannot transform the variable loads, making them more vulnerable to choking if not handled with proper care and guidelines.